Key Processes and Modules

1. Winding Material Feed

· Application: Automatic feeding and alignment of electrode and separator materials for cell winding.

· Specifications:

o Material Width: 40–80 mm.

o Material Thickness:

■ Electrode: 0.04–0.1 mm.

■ Separator: 0.01–0.03 mm.

o Tension Control: Servo-based, ±5% deviation.

o Feeding Speed: Up to 5 m/min.

2. Flattening and Adhesive Application

· Application: Ensures precise layering and adhesive application for consistent winding quality.

· Specifications:

o Flattening Tolerance: ±0.02 mm.

o Adhesive Application Width: 1–10 mm.

o Adhesive Precision: ±0.1 mm.

o Cycle Time: ≤2 seconds per layer.

3. Hypot (High Potential) Testing

· Application: Verifies insulation and safety standards of wound cells.

· Specifications:

o Voltage Range: 500–3000 V DC.

o Leakage Current Threshold: ≤1 μA.

o Testing Speed: ≤3 seconds per cell.

o Pass/Fail Criteria: Customizable through PLC.

4. Battery Cell Case Insertion

· Application: Automated insertion of the wound cell into the cylindrical case.

· Specifications:

o Case Dimensions:

■ Diameter: 10–30 mm.

■ Height: 30–80 mm.

o Cycle Time: ≤5 seconds per unit.

o Positioning Accuracy: ±0.05 mm.

5. Positive Current Collector Laser Welding

· Application: Attaches the positive electrode to the battery cap with high-precision laser welding.

· Specifications:

o Laser Power: 300–500 W.

o Wavelength: 1064 nm.

o Weld Spot Diameter: 0.1–0.3 mm.

o Welding Speed: ≤5 seconds per weld.

o Material Compatibility: Nickel, copper, aluminum.

6. Negative Current Collector Laser Welding

· Application: Attaches the negative electrode to the battery can with laser welding.

· Specifications:

o Laser Power: 300–500 W.

o Wavelength: 1064 nm.

o Weld Spot Diameter: 0.1–0.3 mm.

o Welding Speed: ≤5 seconds per weld.

o Material Compatibility: Nickel, copper, aluminum.

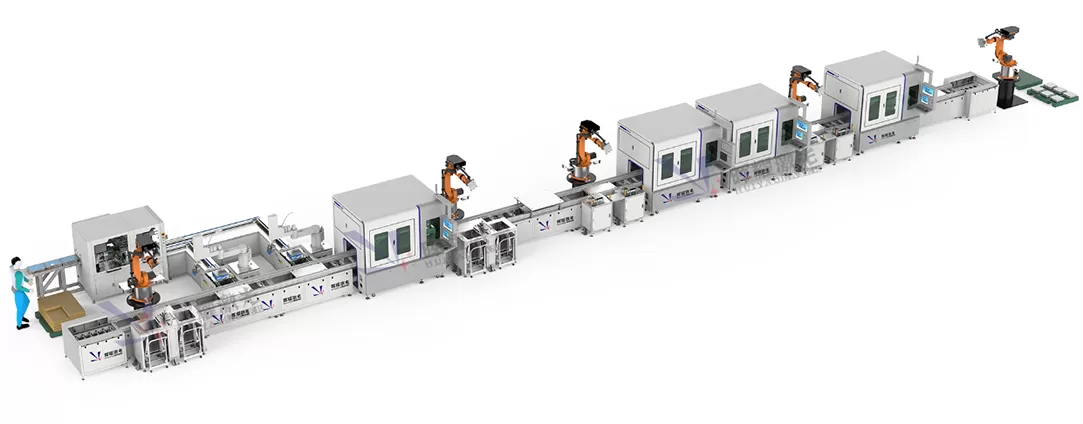

Production Line Specifications

· Overall Dimensions:

o Length: 20,000 mm.

o Width: 5,000 mm.

o Height: 2,500 mm.

· Weight: Approximately 10,000 kg.

· Cycle Time: 15–20 seconds per cell (process-dependent).

· Production Capacity: Up to 2000 cells/hour.

· Automation Level: Fully automated with robotic handling.

Vision and Quality Inspection Systems

· Pre-Welding Alignment:

o High-resolution CCD cameras ensure ±0.02 mm positioning accuracy.

· Post-Weld Inspection:

o Surface continuity and defect detection via AI-based algorithms.

· Adhesive Application Check:

o Vision-guided inspection with adjustable thresholds.

· Data Logging:

o Process results saved to a central server in CSV format.

Control and Interface

· Control System: Centralized PLC with distributed modular controllers for each station.

· HMI:

o 15-inch touchscreen with multilingual support.

o Real-time process monitoring and troubleshooting.

· IoT Connectivity:

o Remote diagnostics and software updates via Ethernet or cloud.

Safety Features

· Enclosures: Fully enclosed stations with interlocks.

· Emergency Stops: Strategically placed across the line.

· Laser Safety: Class 1 laser protection with certified viewing windows.

· Overload Protection: Integrated sensors to detect motor or component stress.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 50 kW.

· Control Voltage: 24V DC for auxiliary systems.

Cooling System

· Type: Water cooling system for laser and electronic components.

· Cooling Capacity: 20 kW.

· Flow Rate: 10–20 L/min.

Environmental Requirements

· Operating Environment:

o Temperature: 15–30°C.

o Humidity: ≤60% RH (non-condensing).

· Noise Level: ≤70 dB during operation.

· Installation Space: Minimum clearance of 1,500 mm around the line.

Maintenance and Warranty

· Maintenance Schedule:

o Weekly: Inspect lenses, alignment systems, and sensors.

o Monthly: Calibrate laser systems and check adhesive applicators.

o Quarterly: Full diagnostics of mechanical and electrical systems.

· Warranty Period:

o Standard: 12 months.