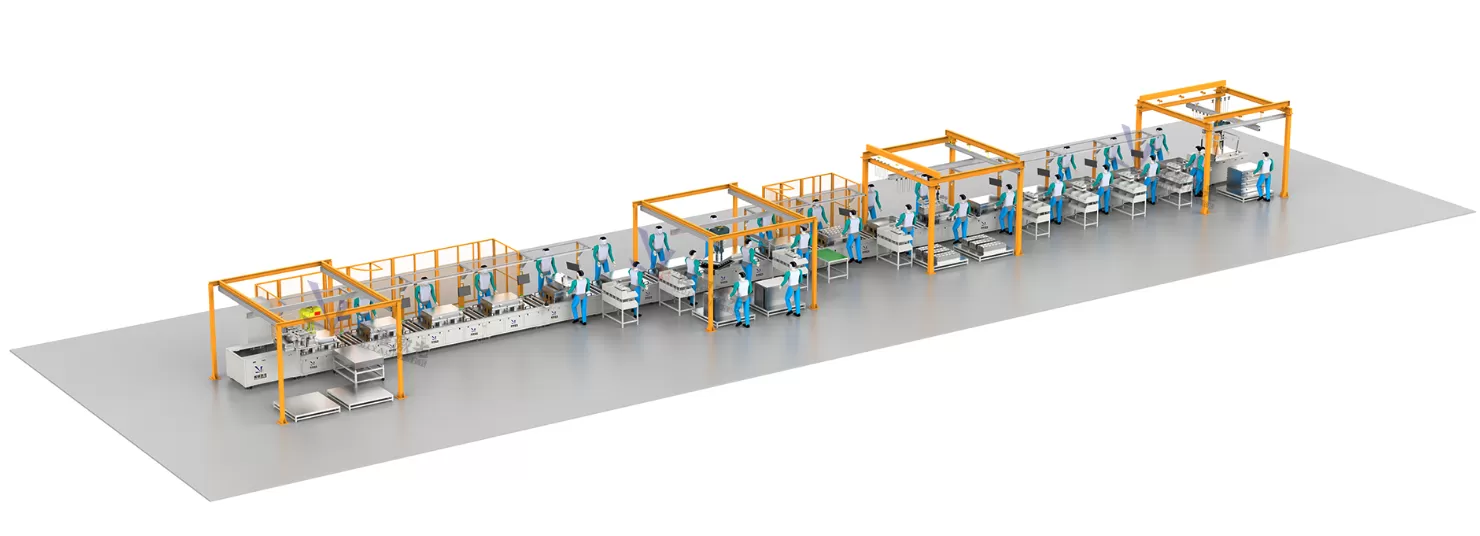

The EV Prismatic Battery Module PACK Assembly Line is a fully automated production system for assembling prismatic battery modules into complete battery PACKs. This line integrates multiple processes including cell sorting, module assembly, welding, inspection, and PACK integration, ensuring high precision, efficiency, and product reliability.

In the rapidly evolving energy storage and electric vehicle (EV) industries, prismatic battery PACK assembly plays a crucial role in ensuring high-performance and long-lasting battery systems. As a leading supplier of prismatic battery PACK assembly production lines, we provide advanced, automated, and efficient solutions tailored to the needs of battery manufacturers worldwide.

Our production line is designed to streamline battery assembly processes, improve production efficiency, and ensure the highest quality standards for prismatic lithium-ion battery PACKs. Whether you are in the EV industry, energy storage sector, or consumer electronics market, our battery PACK assembly solutions help enhance productivity, reduce labor costs, and maintain consistent product quality.

Key Processes and Modules

1. Battery Cell Sorting Station

· Function: Automatic sorting of battery cells based on voltage, capacity, and internal resistance.

· Specifications:

o Sorting Accuracy: ±0.01% rdg.±3 dgt (voltage), +0.5% rdg. +10 dgt (resistance).

o Throughput: 720 cells/hour.

2. Module Frame Assembly

· Function: Automatic assembly of prismatic battery cells into the module frame.

· Specifications:

o Frame Size: Customizable for module dimensions.

o Positioning Accuracy: ±0.1 mm.

o Cycle Time: ≤5 seconds per cell.

3. Busbar Welding Station

· Function: Laser welding of busbars to battery terminals for electrical connection.

· Specifications:

o Laser Type: Fiber laser, 3000-4000w.

o Welding Accuracy: ±0.05 mm.

o Welding Speed: ≤5 seconds per weld.

4. Insulation and Protection Assembly

· Function: Placement of insulating materials and protective components to ensure safety.

· Specifications:

o Material Compatibility: Mylar, foam pads, and plastic shields.

o Placement Accuracy: ±0.1 mm.

o Automation Level: Fully automated with robotic handling.

5. Module Testing Station

· Function: Electrical and functional testing of assembled modules.

· Specifications:

o Testing Parameters: Voltage, internal resistance, insulation, and thermal performance.

o Testing Speed: ≤30 seconds per module.

o Data Storage: Test results logged for traceability.

6. PACK Assembly and Integration

· Function: Assembly of battery modules into the PACK housing, including cooling system and connectors.

· Specifications:

o PACK Size Range:

■ Length: 500–1200 mm.

■ Width: 400–800 mm.

■ Height: 100–300 mm.

o Positioning Accuracy: ±0.2 mm.

o Cycle Time: ≤120 seconds per PACK.

7. Final Testing and Inspection

· Function: Comprehensive testing of the final PACK for performance and safety.

· Specifications:

o Testing Parameters: Voltage, capacity, insulation, short-circuit, and helium leak detection.

o Testing Speed: ≤2 minutes per PACK.

o Quality Criteria: Pass/fail thresholds programmable via software.

Production Line Specifications

· Overall Dimensions:

o Length: 50,000 mm.

o Width: 8,000 mm.

o Height: 3,000 mm.

· Weight: Approximately 25,000 kg.

· Production Capacity: Up to 30 PACKs/hour.

· Automation Level: Fully automated with robotic and vision systems.

Vision and Quality Inspection Systems

· Alignment Cameras:

o Accuracy: ±0.02 mm for component placement.

o Resolution: 5 MP high-speed cameras.

· Defect Detection: AI-based algorithms for weld quality, misalignment, and surface anomalies.

· Data Logging: All inspection results stored for traceability.

Control and Interface

· Control System: Modular PLC with real-time monitoring and control.

· Human-Machine Interface (HMI):

o 10-inch touchscreen with multi-language support.

o Parameter adjustment and process monitoring.

· IoT Connectivity:

o Remote diagnostics, software updates, and production analytics.

Safety Features

· Enclosures: Fully enclosed with interlocks for each station.

· Emergency Stops: Strategically placed along the line.

· Welding Safety: Laser enclosures and certified protective glass.

· Electrical Safety: Overload and fault detection systems.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 250 kW.

· Control Voltage: 24V DC for auxiliary systems.

Cooling System

· Type: Centralized water cooling for laser systems and high-power electronics.

· Cooling Capacity: 10kw.

· Flow Rate: 20–40 L/min.

Environmental Requirements

· Operating Environment:

o Temperature: 15–30°C.

o Humidity: ≤60% RH (non-condensing).

· Noise Level: ≤75 dB during operation.

· Installation Space: Minimum clearance of 2,000 mm around the line.

Maintenance and Warranty

· Maintenance Schedule:

o Weekly: Inspect vision systems, welders, and alignment mechanisms.

o Monthly: Calibration of testing equipment and laser systems.

o Quarterly: Comprehensive diagnostics of all stations.

· Warranty Period:

o Standard: 12 months.

o Extended: Up to 36 months available upon request.

Why Choose Our Prismatic Battery PACK Assembly Line?

1. Fully Automated and High Precision

Our prismatic battery PACK assembly line integrates advanced automation technology to ensure high-speed, high-precision assembly. From cell sorting, module stacking, and laser welding to BMS installation and final testing, every step is optimized for efficiency and accuracy.

2. Customizable Solutions for Diverse Applications

We understand that different industries have unique requirements. Our prismatic battery PACK assembly systems can be customized to accommodate various cell sizes, PACK configurations, and specific production capacities, making them ideal for EV battery manufacturers, renewable energy storage providers, and industrial battery suppliers.

3. Strict Quality Control & Safety Measures

Our production line features real-time monitoring, defect detection, and intelligent error correction to ensure every battery PACK meets strict quality and safety standards. With comprehensive quality checks, including voltage, resistance, and insulation tests, we help manufacturers minimize defects and enhance battery reliability.

4. Scalability and High Production Efficiency

Our modular design allows manufacturers to scale production efficiently, meeting growing market demands without compromising quality. Our solutions reduce human intervention, lower labor costs, and enhance overall manufacturing throughput.

5. Advanced Welding and Bonding Technologies

We employ state-of-the-art laser welding, ultrasonic bonding, and adhesive automation to ensure robust electrical and mechanical connections. These techniques improve battery PACK durability, thermal management, and overall performance.