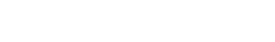

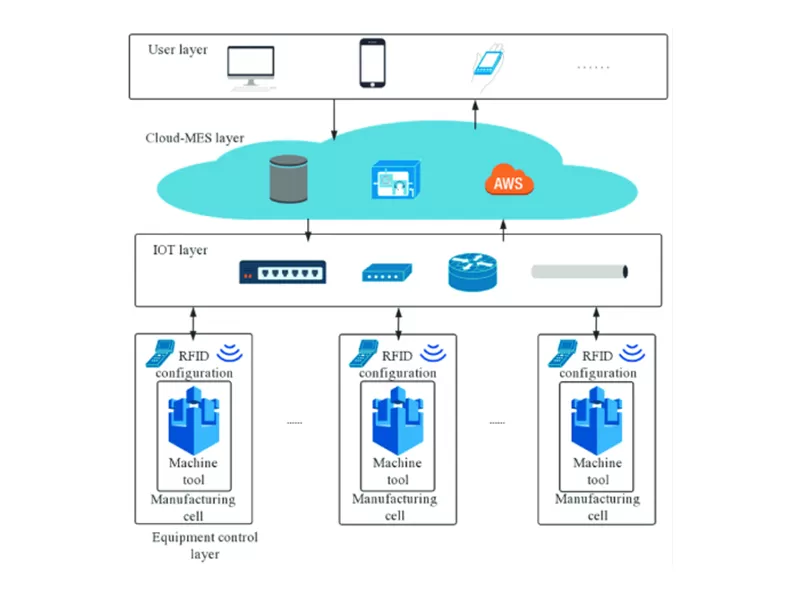

EV Battery Smart Factory Solution is an advanced, intelligent manufacturing system designed to enhance the production efficiency, quality, and safety of EV battery packs. By integrating automation, digitalization, and AI-driven technologies, the smart factory ensures high-precision manufacturing with minimal human intervention.

Key Features of an EV Battery Smart Factory

✅ Fully Automated Production – Reduces labor costs and improves consistency.

✅ AI & Big Data Integration – Enables real-time monitoring, predictive maintenance, and quality control.

✅ IoT & Digital Twin Technology – Simulates production processes for optimization.

✅ Flexible & Scalable Manufacturing – Supports different battery chemistries and pack configurations.

✅ Smart Quality Control System – AI-driven defect detection and automated testing.

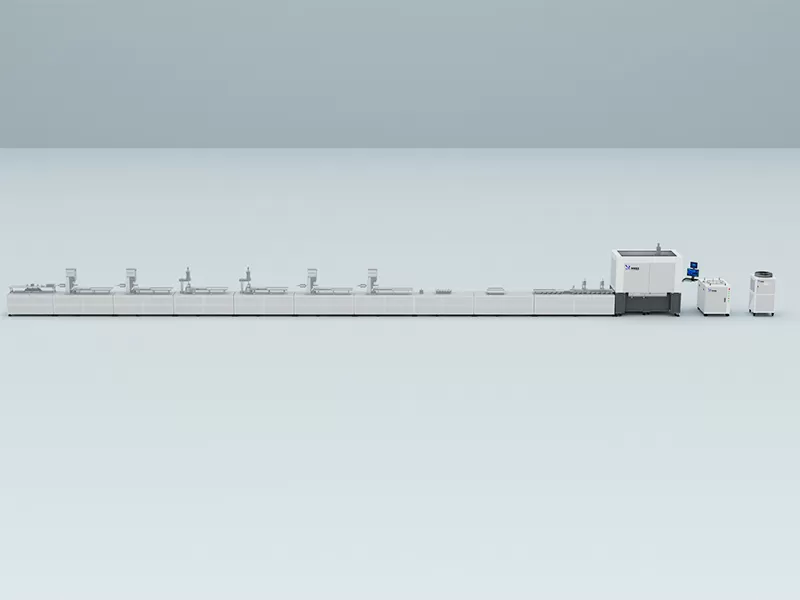

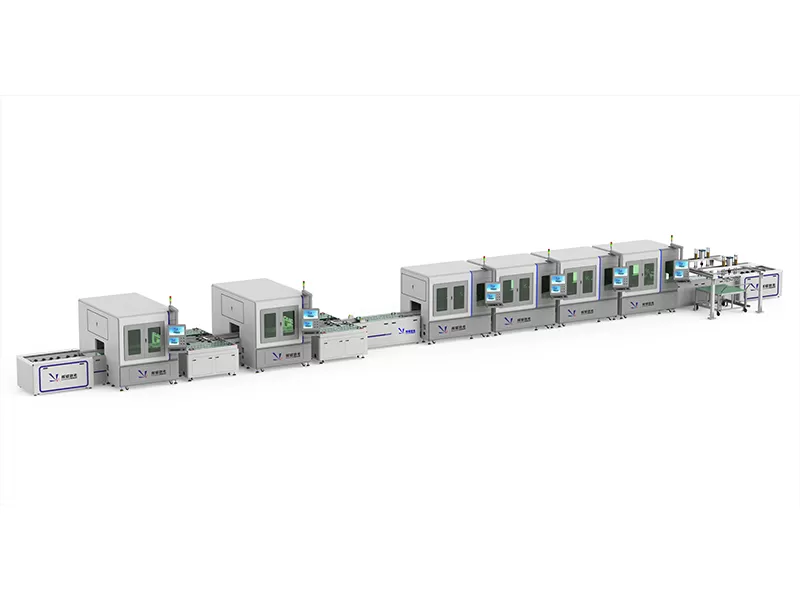

Smart Factory Production Process

Step 1: Battery Cell Sorting & Preparation

AI-driven optical inspection for cell defects.

Automated sorting based on voltage, capacity, and internal resistance.

Smart warehousing and real-time inventory management.

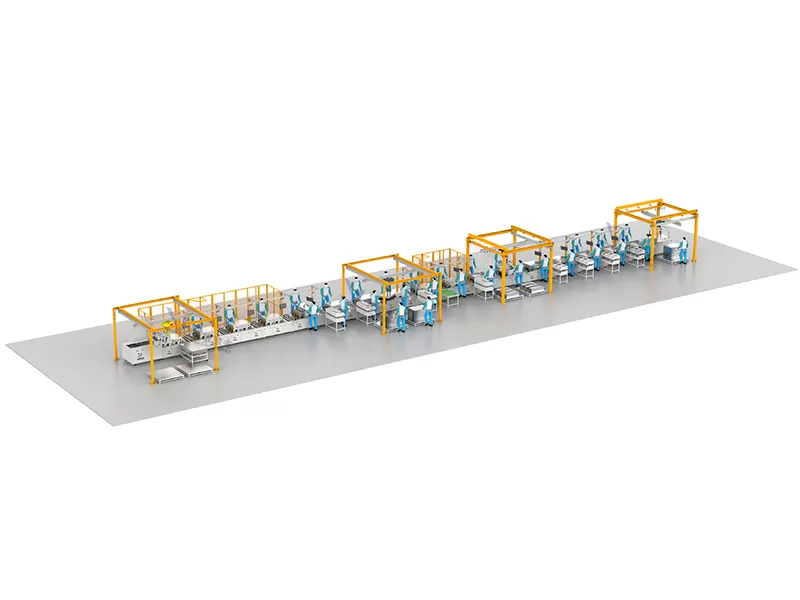

Step 2: Module Assembly

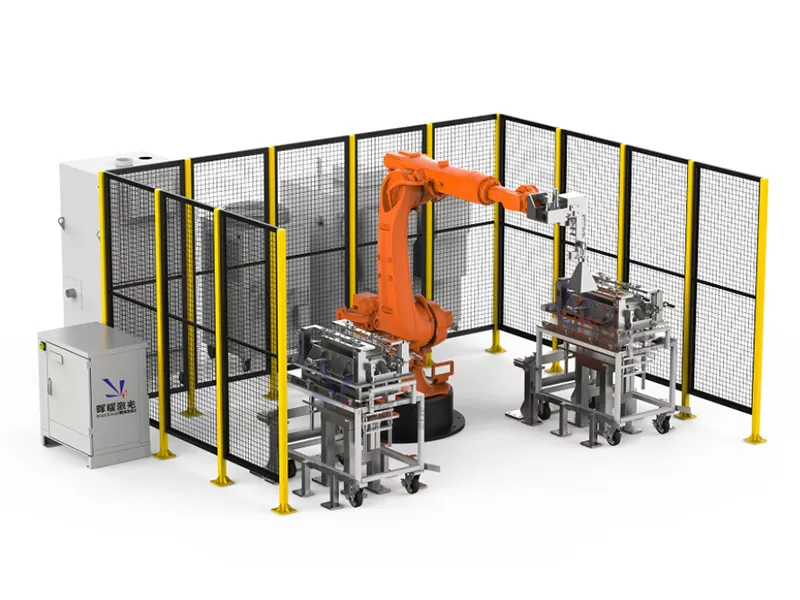

Robotic cell stacking & welding (laser welding, ultrasonic welding).

Automated application of thermal management materials.

AI-powered BMS pre-calibration and testing.

Step 3: Battery Pack Assembly

Fully automated module integration (robotic handling & precise alignment).

Smart cooling system installation (liquid/air cooling).

AI-driven sealing and enclosure assembly for waterproofing.

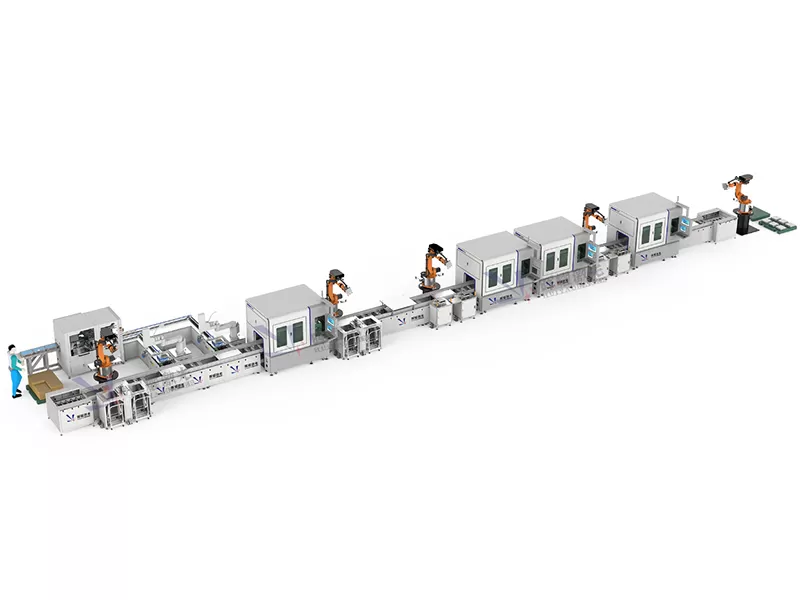

Step 4: Intelligent Testing & Quality Control

End-of-line (EOL) automated testing for voltage, resistance, and thermal performance.

AI-powered defect detection through machine vision.

Real-time data analytics for predictive maintenance.

Applications of Smart Battery Manufacturing

Electric Vehicles (EVs)

Energy Storage Systems (ESS)

Hybrid Electric Vehicles (HEVs)

Industrial & Commercial Battery Solutions