In the rapidly evolving energy storage industry, where efficiency, safety, and durability are paramount, every component of a battery module plays a crucial role. Among these components, the steel belt often remains overlooked despite its significant contribution to the overall performance and reliability of energy storage systems. Steel belts, typically used to secure and stabilize battery modules, provide a wide range of benefits in terms of structural integrity, safety, thermal management, and manufacturing efficiency. In this article, we’ll delve into the importance of steel belts in battery modules and their role in shaping the future of energy storage.

1. Enhancing Structural Integrity

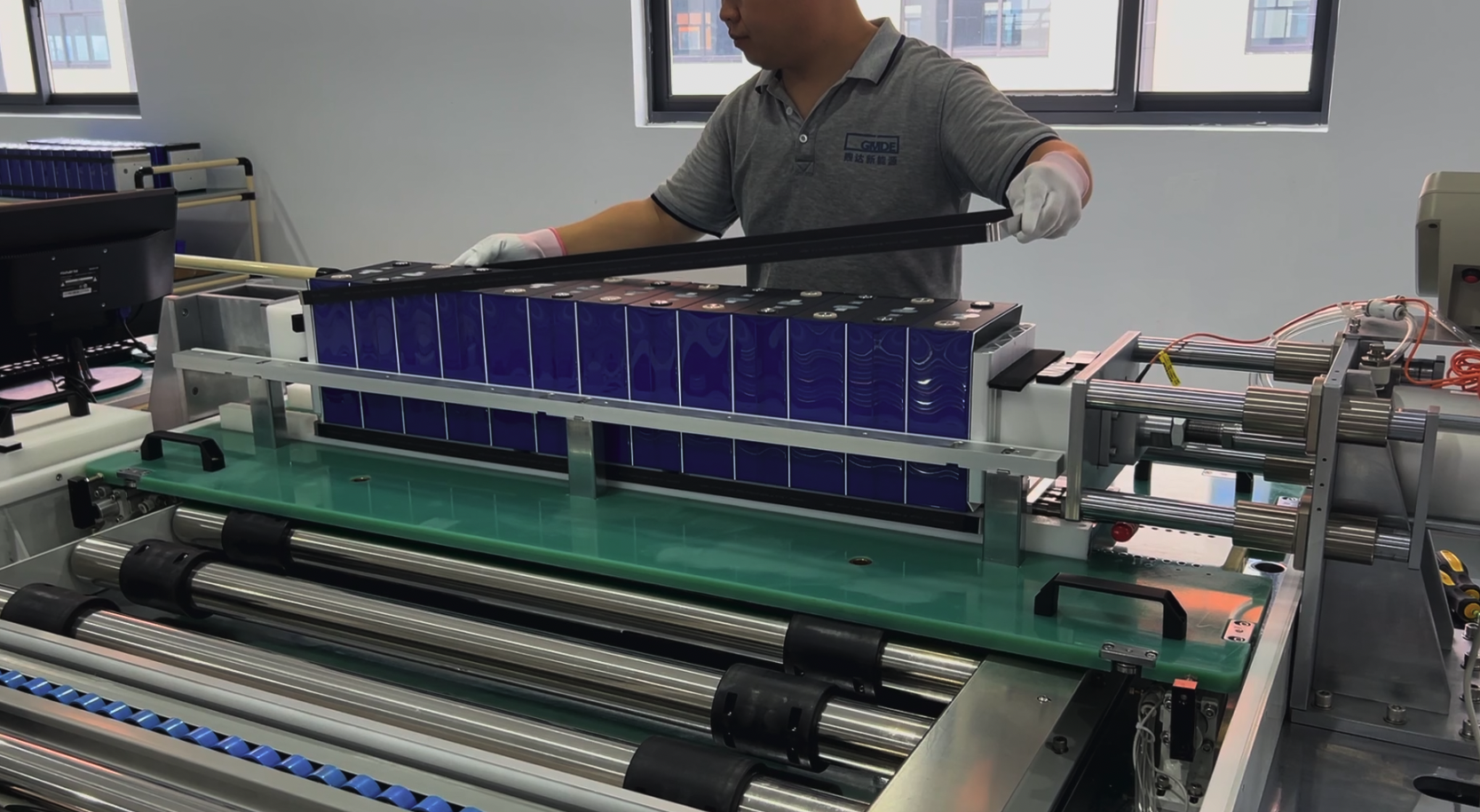

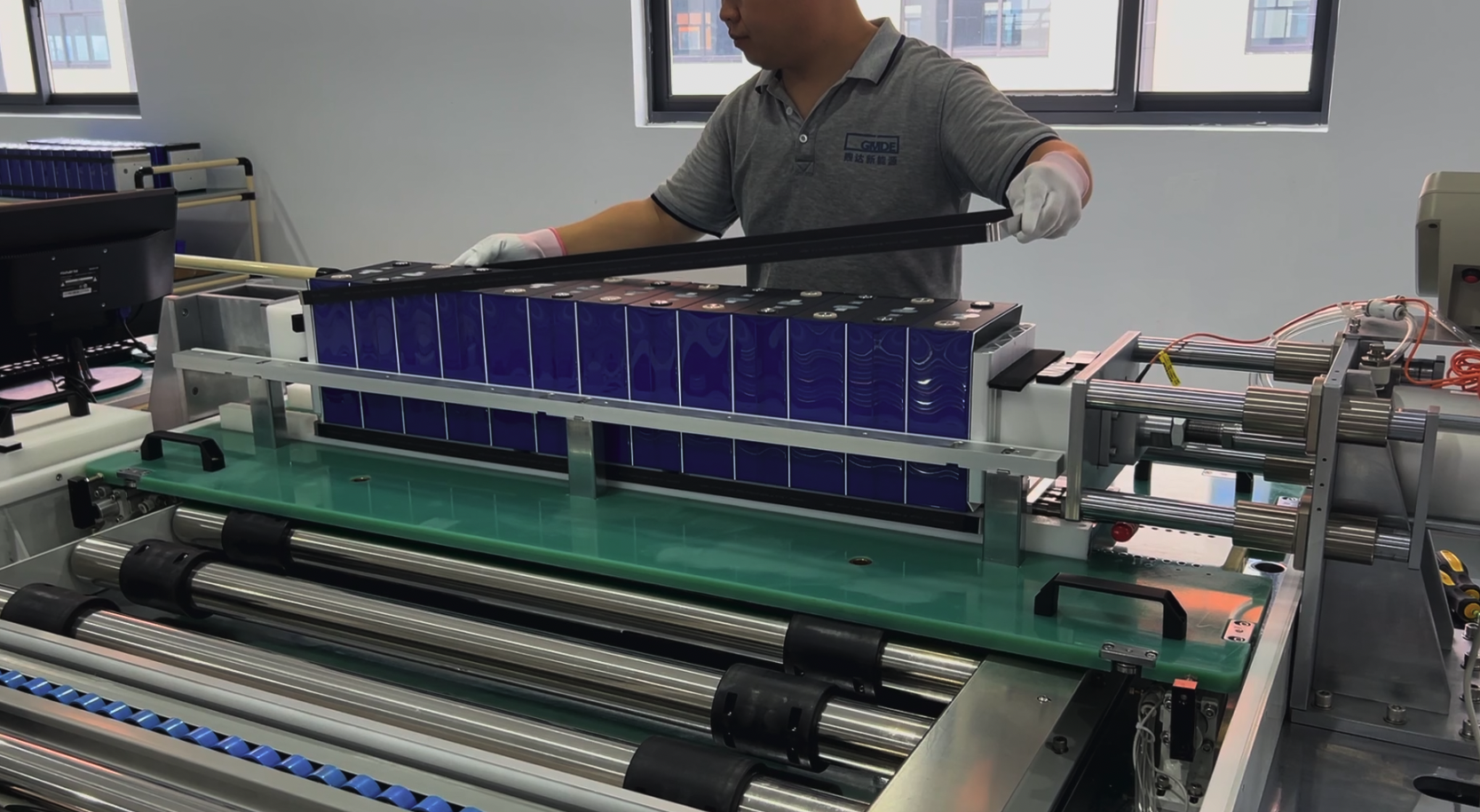

The primary function of steel belts in battery modules is to enhance structural stability and ensure that the battery cells remain securely in place. This is especially critical as battery modules often consist of numerous tightly packed battery cells.

• Prevention of Cell Movement: During operation, battery cells may expand, contract, or shift due to thermal and mechanical stresses. Steel belts ensure that the cells remain fixed in their designated positions, preventing damage to interconnections and internal components.

• Withstanding External Forces: In applications such as electric vehicles (EVs) and grid energy storage systems, battery modules are subjected to vibrations, shocks, and external impacts. Steel belts provide a robust reinforcement, enabling the module to resist these forces without compromising its structural integrity.

• Compact Design: Steel belts help create a compact and lightweight design by tightly securing the battery cells. This enables manufacturers to optimize space utilization, especially in applications where high energy density is critical.

2. Improving Safety

Safety is one of the most critical considerations in the energy storage industry. The use of steel belts in battery modules directly contributes to mitigating potential risks.

• Preventing Thermal Runaway Propagation: In the event of a thermal runaway, where one cell overheats and risks affecting neighboring cells, the steel belt acts as a containment measure. Its strength and rigidity can help isolate affected cells, preventing the runaway from spreading and reducing the likelihood of catastrophic failure.

• Pressure Containment: As battery cells undergo chemical reactions during charging and discharging, they may generate internal pressure. Steel belts provide additional strength to withstand this pressure, reducing the risk of deformation or rupture.

• Fire Resistance: Unlike other materials, steel belts are non-combustible and can withstand high temperatures. This property makes them a reliable choice for enhancing the safety of battery modules, especially in extreme conditions.

3. Thermal Management Support

Thermal management is a crucial aspect of maintaining the efficiency and safety of battery modules. Steel belts can indirectly contribute to this by assisting in heat dissipation and ensuring uniform thermal behavior across the module.

• Heat Distribution: Steel is a good conductor of heat. By tightly securing the cells, steel belts can help distribute heat more evenly across the module, minimizing the risk of hotspots and ensuring consistent cell performance.

• Structural Support for Cooling Systems: In many energy storage systems, cooling systems are integrated into the battery design. Steel belts provide the necessary structural stability to securely mount or support cooling components, ensuring their proper function.

4. Extending Battery Module Lifespan

The longevity of a battery module is influenced by the stability of its internal components. Steel belts play an essential role in ensuring that the battery cells remain undamaged and operate efficiently over time.

• Reducing Mechanical Stress: The constant expansion and contraction of cells during charge and discharge cycles can cause wear and tear. Steel belts reduce mechanical stress by holding the cells firmly together and distributing pressure evenly.

• Minimizing Damage from Vibration: Prolonged exposure to vibration can lead to microcracks and internal damage in battery cells. Steel belts mitigate this by absorbing and distributing mechanical energy, thus protecting the cells.

5. Supporting Modular Design and Scalability

In the energy storage industry, modular design is becoming increasingly popular due to its scalability and ease of maintenance. Steel belts support this trend by providing a secure and flexible solution for constructing modular battery systems.

• Easy Assembly and Disassembly: Steel belts can be designed for easy installation and removal, facilitating the assembly and maintenance of modular battery systems. This simplifies repairs and upgrades, making the system more cost-effective over its lifecycle.

• Scalable Design: As energy demands increase, systems often need to scale up by adding more battery modules. Steel belts help ensure that additional modules can be securely integrated without compromising the stability or safety of the overall system.

6. Durability and Reliability

Steel belts are highly durable, offering long-lasting performance even in harsh environmental conditions. This makes them an ideal choice for energy storage applications.

• Corrosion Resistance: Many steel belts are treated with anti-corrosion coatings to withstand exposure to moisture, chemicals, and other environmental factors. This ensures their reliability in outdoor or high-humidity storage systems.

• High Strength-to-Weight Ratio: Steel belts provide excellent strength without adding excessive weight, making them suitable for applications such as EVs where weight is a critical factor.

• Resistance to Wear and Tear: Unlike other materials that may degrade over time, steel belts maintain their structural integrity even after prolonged use, ensuring the long-term reliability of the battery module.

7. Cost Efficiency in Manufacturing

From a manufacturing perspective, steel belts offer several cost advantages.

• Simplified Assembly Process: Using steel belts to secure battery cells reduces the need for complex mechanical fasteners or adhesives, streamlining the assembly process and reducing production time.

• Recyclability: Steel belts are recyclable, making them an environmentally friendly option that aligns with the sustainability goals of the energy storage industry.

• Lower Maintenance Costs: The durability of steel belts reduces the need for frequent replacements or repairs, lowering the overall maintenance costs of battery systems.

Conclusion: A Small Component with Big Impacts

While steel belts may seem like a minor component in battery modules, their importance cannot be overstated. They contribute to structural integrity, safety, thermal management, and durability, all of which are critical for the performance and reliability of energy storage systems. As the energy storage industry continues to grow and innovate, the role of steel belts will remain vital in ensuring that battery modules meet the ever-increasing demands for safety, efficiency, and sustainability.

By integrating steel belts into battery design, manufacturers can not only enhance the performance of their products but also build a foundation for the future of clean energy solutions. From electric vehicles to grid storage systems, steel belts are a testament to how even the smallest details can have a significant impact on advancing energy storage technology.

About Huiyao Laser Technology (Luoyang) Co., Ltd.

Huiyao Laser Technology (Luoyang) Co., Ltd. is a leading provider of advanced solutions for the energy storage and electric vehicle industries. Since its establishment in 2019, the company has been dedicated to delivering turnkey solutions, specializing in intelligent manufacturing equipment such as battery module PACK assembly lines and laser welding machines. With cutting-edge technology, a focus on innovation, and a commitment to quality, Huiyao Laser serves over 130 customers worldwide, contributing to the advancement of safer, more efficient energy storage systems.