Understanding Laser Marking

Laser marking uses a focused beam of light to leave permanent marks on various materials. These marks can include serial numbers, barcodes, logos, and even intricate patterns. Unlike traditional marking methods, laser marking offers several advantages:

· Durability: Marks are resistant to wear, heat, and corrosion.

· High Precision: Achieves crisp, detailed marks even on small surfaces.

· Non-Contact Process: Prevents damage to the material being marked.

· Eco-Friendly: Eliminates the need for inks, chemicals, or consumables.

· Versatility: Applicable to metals, plastics, ceramics, glass, and more.

Applications of Huiyao Laser Marking Technology

Huiyao Laser Technology provides versatile solutions tailored to the unique needs of various industries. Here’s how laser marking is revolutionizing different sectors:

1. Automotive Industry

· Part Traceability: Marks VINs, QR codes, and batch numbers on components to streamline supply chain management.

· Aesthetic Branding: Adds logos and branding elements to automotive parts with a premium finish.

· Durable Identification: Ensures permanent markings on engine parts, ensuring compliance with safety regulations.

2. Electronics and Semiconductors

· Micro Marking: Marks tiny components like PCBs and microchips with high precision.

· Traceability: Adds serial numbers and barcodes to prevent counterfeiting and manage warranties.

· Surface Customization: Creates aesthetically appealing patterns on device casings.

3. Medical Devices

· Regulatory Compliance: Marks unique device identifiers (UDI) on surgical tools, implants, and packaging to meet medical standards.

· Sterility: Non-contact marking ensures no contamination during the process.

· Biocompatible Marks: Suitable for marking titanium and stainless-steel implants.

4. Consumer Goods

· Brand Enhancement: Engraves logos and product information on items like jewelry, watches, and luxury goods.

· Personalization: Enables mass customization for promotional and gift items.

· Anti-Counterfeiting: Marks security features to protect brand authenticity.

5. Aerospace Industry

· Part Identification: Marks aircraft components with data matrix codes for lifecycle management.

· Heat-Resistant Marks: Ensures markings remain legible in extreme environments.

6. Energy Storage Systems (ESS)

· Battery Marking: Applies serial numbers and barcodes to battery cells and modules for traceability in production and logistics.

· Laser Engraving: Creates durable markings on metal and plastic casings of battery packs.

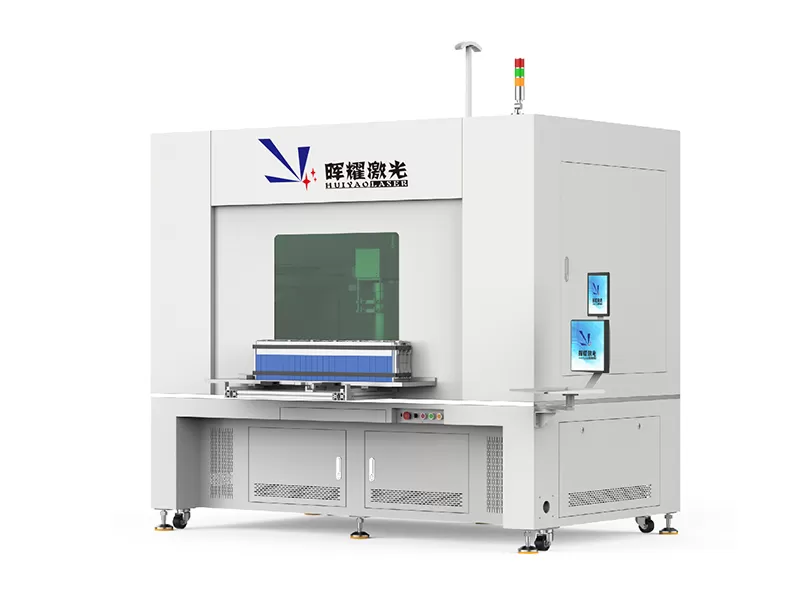

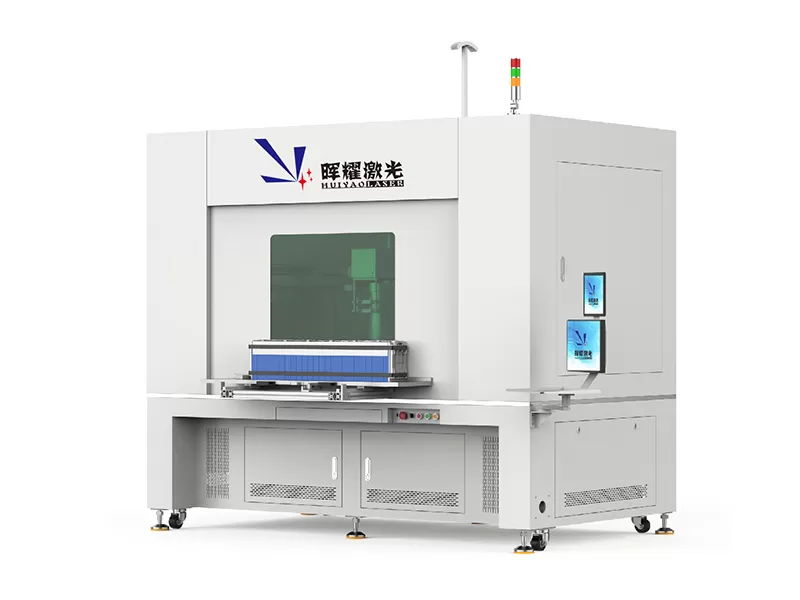

Why Choose Huiyao Laser for Laser Marking?

Huiyao Laser Technology stands out as a trusted partner in delivering innovative marking solutions for industries of all scales.

1. Advanced Technology

Huiyao’s laser marking systems incorporate:

· High-Precision Galvanometers: Enables fast and accurate beam control.

· Intelligent Software: User-friendly interfaces with robust capabilities for custom designs and data integration.

· Multi-Wavelength Options: Supports fiber lasers, CO2 lasers, and UV lasers for various materials and applications.

2. Versatility Across Materials

Huiyao systems are designed to handle diverse materials, including:

· Metals: Steel, aluminum, titanium, and brass.

· Plastics: ABS, polycarbonate, and PVC.

· Organic Materials: Wood, leather, and paper.

· Glass and Ceramics: Ensures crisp marks without cracking or discoloration.

3. Industry Expertise

With extensive experience across sectors, Huiyao Laser offers tailored solutions to ensure optimal performance, reliability, and compliance with industry-specific standards.

4. Customization and Scalability

Huiyao’s solutions are scalable for small businesses and large manufacturing facilities, with flexible customization options to meet unique production needs.

Advantages of Huiyao Laser Marking Technology

· Environmentally Friendly: Eliminates the need for consumables, reducing operational costs and environmental impact.

· High Efficiency: Processes thousands of components per hour with minimal downtime.

· Consistent Quality: Ensures uniform markings across high-volume production runs.

· Minimal Maintenance: Durable designs with extended operational lifespans.

Driving Industry Transformation

Huiyao Laser Technology has established itself as a pioneer in laser marking solutions, driving innovation and excellence in manufacturing. By addressing critical challenges like traceability, compliance, and brand differentiation, Huiyao empowers businesses to stay competitive in a rapidly changing landscape.

Whether you’re in automotive, healthcare, consumer goods, or any other sector, Huiyao Laser Technology offers the expertise and tools to elevate your production capabilities.

Discover the Huiyao Advantage

Partner with Huiyao Laser Technology to unlock the full potential of laser marking in your industry. From product traceability to branding, our solutions are designed to help you achieve precision, efficiency, and success. Contact us today to explore how we can transform your manufacturing processes.