Mechanical Specifications

· Equipment Dimensions:

o Length: 2000 mm

o Width: 1500 mm

o Height: 1900 mm

· Weight: 1500 kg ± 5%

· Frame Material: Reinforced steel frame with powder coating for durability.

· Worktable Material: Anodized aluminum alloy with anti-static surface.

· Motion System: Servo-driven X-Y-Z axes with precision linear guide rails.

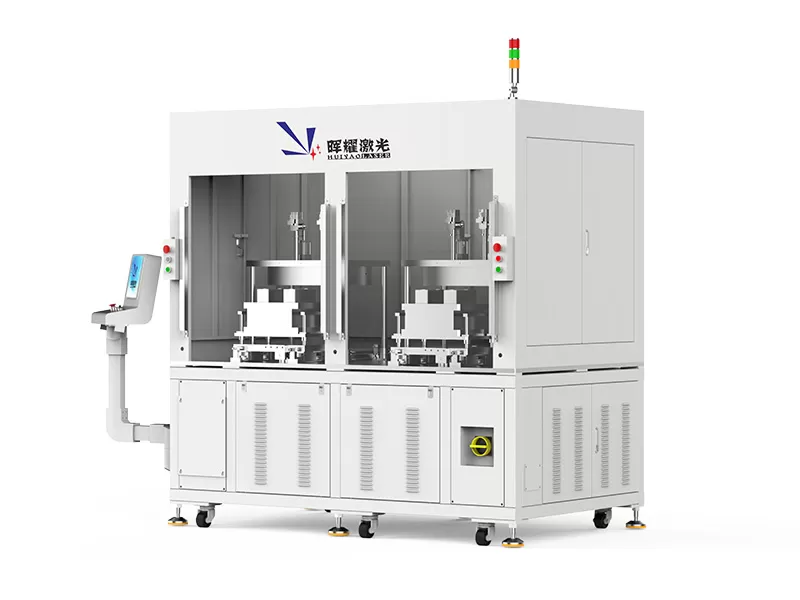

Case Insertion Specifications

· Insertion Accuracy: ±0.1 mm.

· Cell Compatibility:

o Width: 50–100 mm.

o Height: 50–200 mm.

o Thickness: 5–20 mm.

· Insertion Speed: Up to 10 cases per minute (process-dependent).

· Grip Mechanism: Pneumatic or servo-controlled gripper with adjustable force for different cell materials.

· Case Materials: Aluminum, stainless steel, and polymer.

Top Cap Pre-Welding Specifications

· Welding Technology:

o Laser Welding (standard).

o Optional: Ultrasonic or Resistance Welding.

· Laser Power: 500–2000 W (adjustable).

· Welding Spot Size: 0.2–0.5 mm (programmable).

· Pre-Welding Accuracy: ±0.05 mm.

· Cap Material Compatibility: Aluminum, nickel, and copper.

· Pre-Welding Speed: Up to 8 welds per minute.

Vision and Alignment System

· Alignment Accuracy: ±0.03 mm.

· Camera:

o Type: Industrial-grade CCD camera.

o Resolution: 5 MP with real-time defect detection.

· Lighting: Adjustable LED for enhanced visibility of cases and caps.

· Inspection Features:

o Pre-insertion cell alignment.

o Post-welding inspection for proper cap positioning and weld integrity.

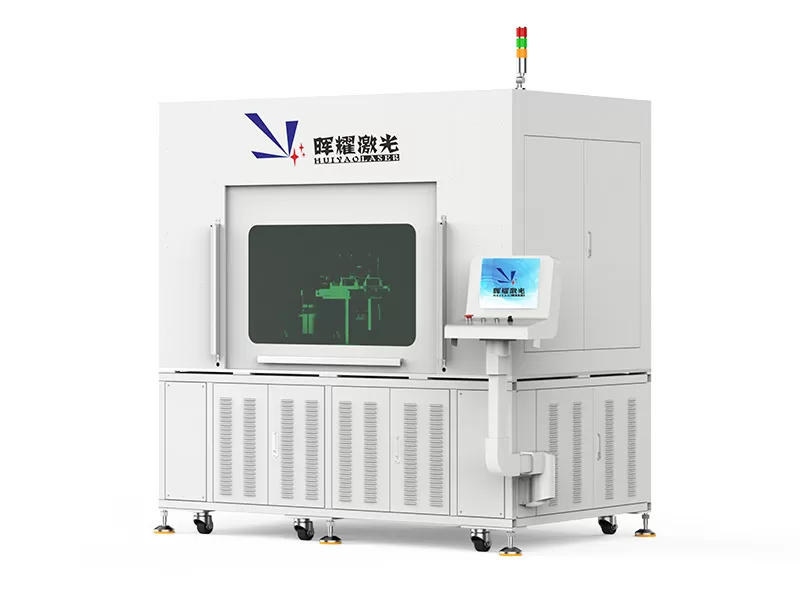

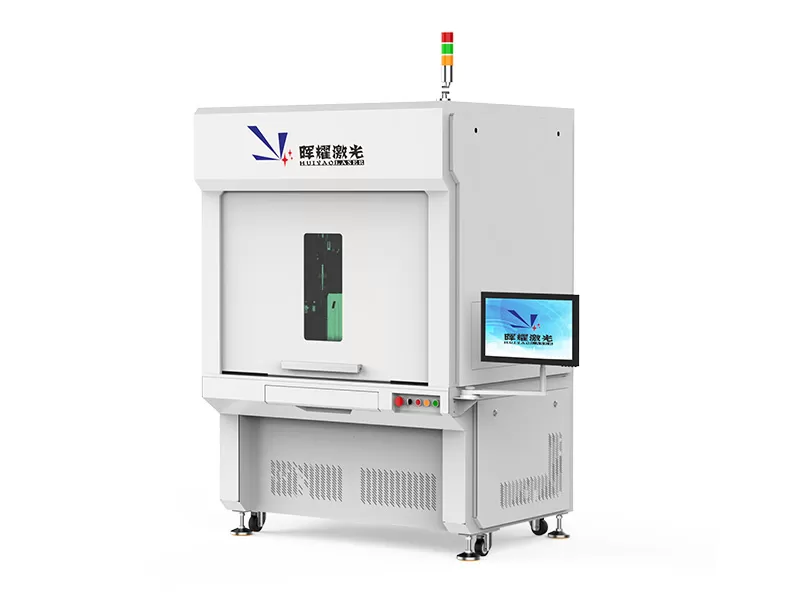

Control and Interface

· Control System: PLC with integrated HMI for seamless operation.

· Interface:

o 12-inch touchscreen with intuitive UI.

o Multi-language support (English, Chinese, others).

· Programmable Parameters:

o Case insertion speed and force.

o Welding power, duration, and spot size.

o Recipe storage for various battery types and sizes.

· Data Logging:

o Internal Capacity: 1 TB for process records.

o Export Formats: CSV, PDF via USB, Ethernet, or Wi-Fi.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 8 kW.

· Control Voltage: 24V DC for auxiliary systems.

Safety Features

· Emergency Stop: Strategically placed buttons on the front and rear panels.

· Overload Protection: Real-time monitoring of force during case insertion and cap welding.

· Laser Safety: Class 1 laser safety enclosure with interlock system.

· Protective Enclosure: Transparent cover with interlocks to prevent operation during maintenance.

· Error Alarms: Audible and visual alarms for misalignment, insertion failure, or welding defects.

Environment & Installation

· Operating Environment:

o Temperature: 10–35°C

o Humidity: ≤60% RH (non-condensing).

· Noise Level: ≤75 dB during operation.

· Installation Requirements:

o Flat, vibration-free surface.

o Minimum clearance: 800 mm on all sides.

Cooling System

· Type: Water-cooled laser module with independent chiller.

· Flow Rate: 10–15 L/min.

· Cooling Power: 3.5 kW.

Maintenance and Warranty

· Maintenance Schedule:

o Weekly: Clean insertion gripper, laser lens, and alignment components.

o Monthly: Inspect servo motors, pneumatic system, and cooling system.

o Quarterly: Full calibration of alignment and welding systems.

· Warranty Period:

o Standard: 12 months.

o Extended: Up to 36 months available upon request.