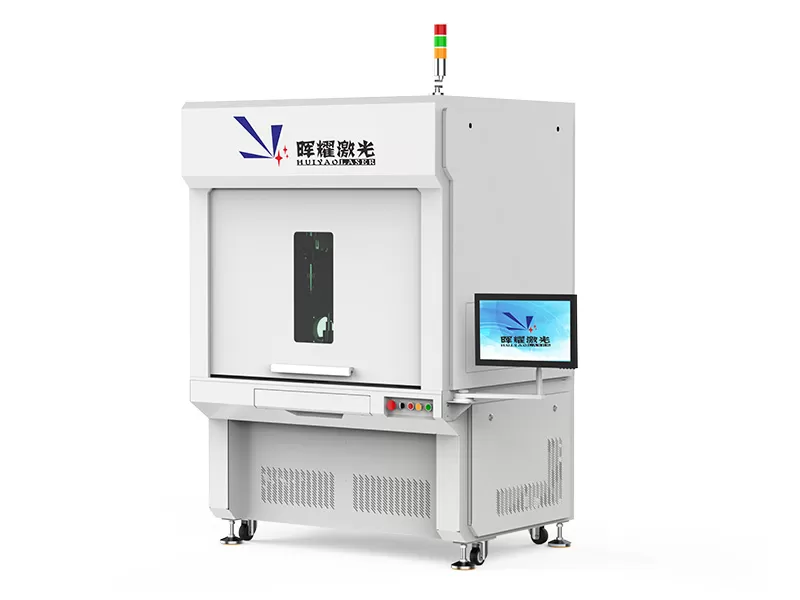

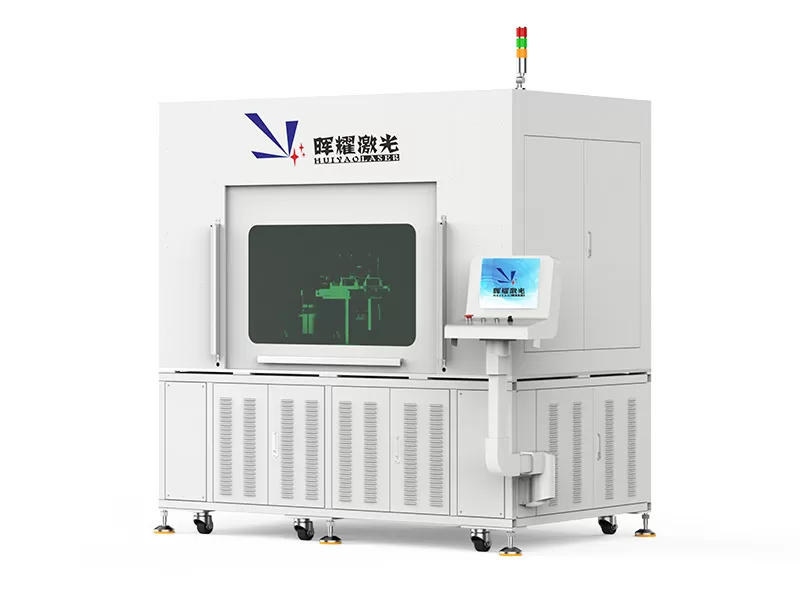

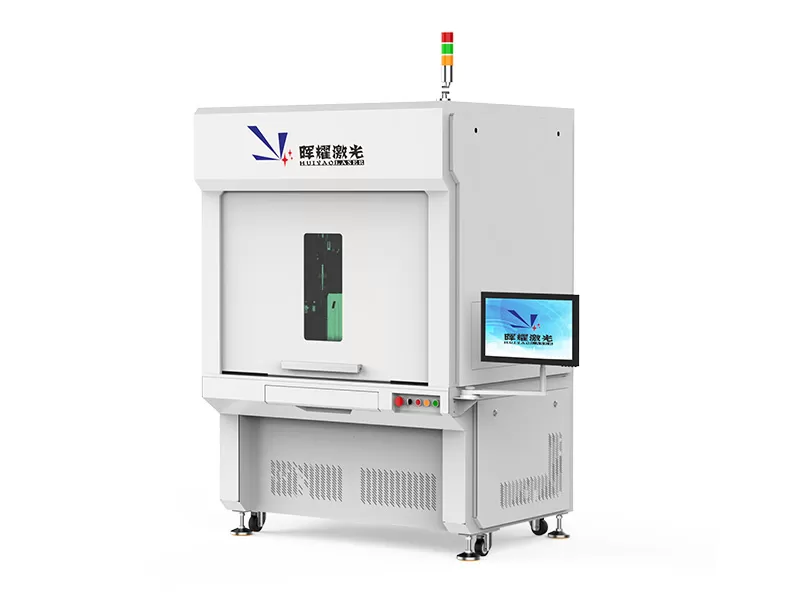

Mechanical Specifications

· Equipment Dimensions:

o Length: 2000 mm

o Width: 1500 mm

o Height: 1800 mm

· Weight: 1200 kg ± 5%

· Frame Material: High-strength steel with anti-corrosion coating.

· Worktable Material: Stainless steel with anti-static properties.

· Test Chamber Size:

o Length: 50–300 mm

o Width: 50–200 mm

o Height: 5–100 mm (adjustable).

Detection Specifications

· Detection Method: Helium mass spectrometry.

· Leak Rate Sensitivity:

o Minimum Detectable Rate: 1 × 10⁻⁶ mbar·L/s.

o Maximum Detectable Rate: 1 × 10⁻² mbar·L/s.

· Testing Accuracy: ±0.05 mbar·L/s.

· Helium Injection Pressure: 0.1–0.5 MPa (adjustable).

· Cycle Time:

o Single Cell Test: ≤30 seconds (including evacuation and measurement).

o Batch Test: Configurable based on chamber size.

· Helium Recovery Rate: ≥98%.

Control and Interface

· Control System: PLC-based system with integrated HMI for test parameter configuration.

· Interface:

o 12-inch capacitive touchscreen with multi-language support.

o Intuitive graphical user interface (GUI) for real-time monitoring and diagnostics.

· Programmable Parameters:

o Helium injection pressure.

o Leak detection threshold.

o Test cycle time.

o Recipe storage for various battery types and sizes.

· Data Logging:

o Internal Storage: 1 TB SSD for historical test data.

o Export Formats: CSV, PDF via USB, Ethernet, or Wi-Fi.

Vacuum System Specifications

· Vacuum Pump Type: Dual-stage rotary vane pump with oil mist eliminator.

· Ultimate Vacuum Level: ≤1 × 10⁻³ mbar.

· Pumping Speed: 50–200 L/min (process-dependent).

· Vacuum Chamber Seal: High-strength silicone gasket with excellent durability.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 6 kW.

· Control Voltage: 24V DC for auxiliary systems.

Safety Features

· Emergency Stop: Dual emergency stop buttons on front and rear panels.

· Pressure Monitoring: Real-time helium injection and evacuation pressure sensors with alarms for anomalies.

· Vacuum Chamber Safety:

o Overpressure relief valves.

o Automatic chamber lock during operation.

· Leak Detection Failure Alert: Audible and visual alarm for leaks exceeding preset thresholds.

· Helium Recovery Safety: Continuous monitoring of recovery system to prevent helium loss or contamination.

Environment & Installation

· Operating Environment:

o Temperature: 15–30°C

o Humidity: ≤60% RH (non-condensing).

· Noise Level: ≤75 dB during operation.

· Installation Requirements:

o Flat, vibration-free surface.

o Clearance: Minimum 800 mm on all sides.

Maintenance and Warranty

· Maintenance Schedule:

o Weekly: Inspect vacuum seals, clean filters, and check helium recovery system.

o Monthly: Calibrate helium sensors and inspect vacuum pump oil levels.

o Quarterly: Comprehensive system calibration and vacuum chamber inspection.

· Warranty Period:

o Standard: 12 months.

o Extended: Up to 36 months available upon request.