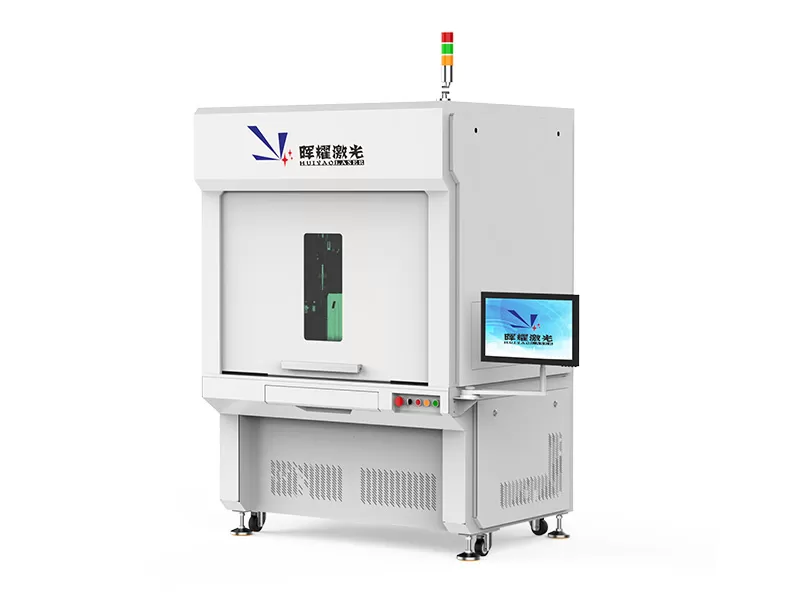

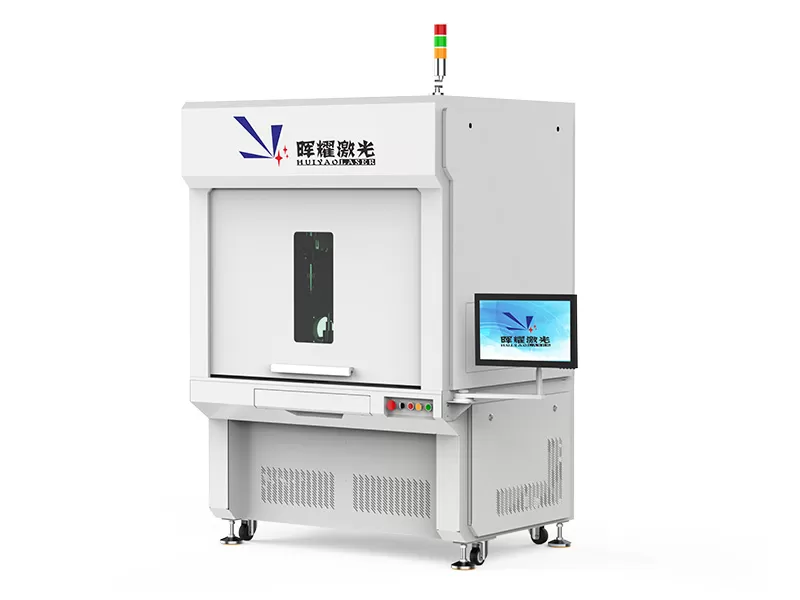

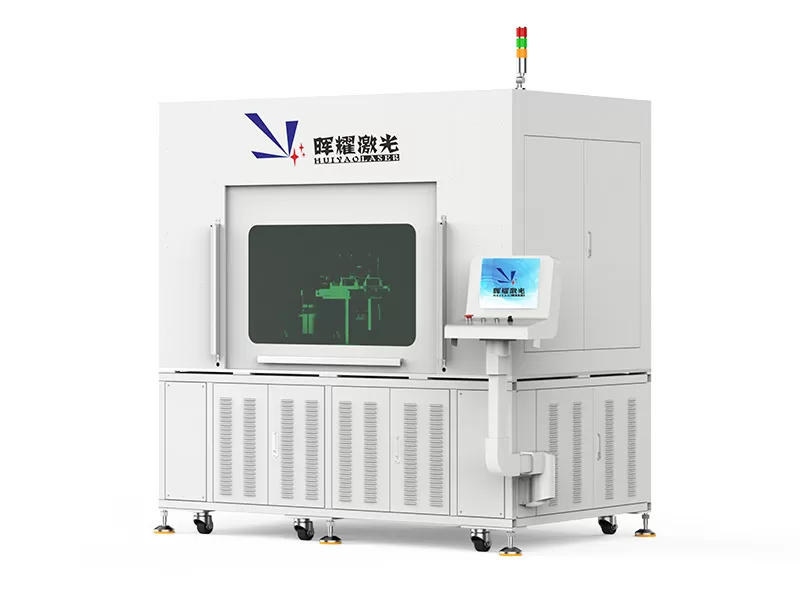

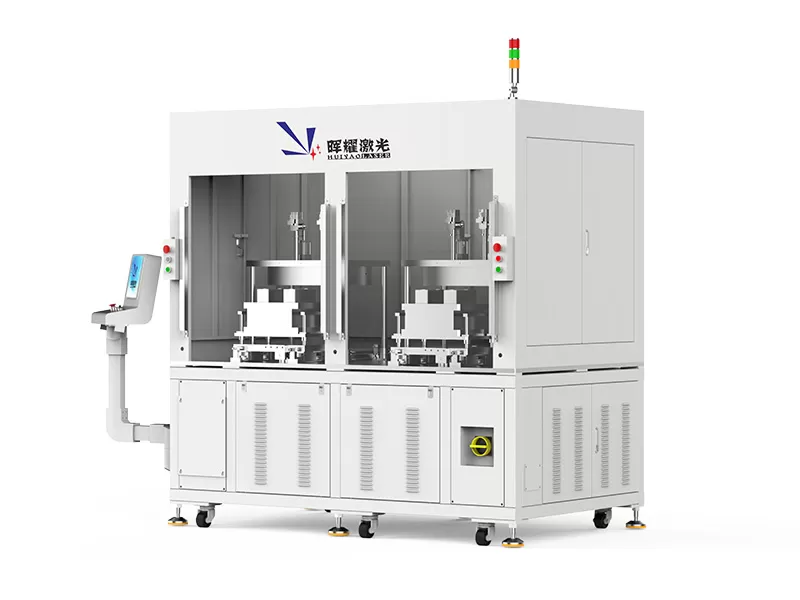

Mechanical Specifications

· Equipment Dimensions:

o Length: 2000 mm

o Width: 1000 mm

o Height: 2500 mm

· Weight: 2500 kg ± 5%

· Frame Material: High-strength carbon steel with powder-coated finish.

· Actuation System: Precision servo motor with ball screw-driven pressing mechanism.

Pressing System

· Pressing Force Range:

o Minimum: 5 kN

o Maximum: 100 kN (adjustable via PLC interface)

· Force Accuracy: ±0.1% (real-time feedback via load cell)

· Pressing Area Dimensions:

o Upper Plate: 300 mm × 400 mm

o Lower Plate: 300 mm × 400 mm

· Parallelism Tolerance: ≤ 0.05 mm

Thermal Control System

· Heating Plate Material: Hardened aluminum alloy with embedded thermal sensors.

· Temperature Control Range: Room temperature to 250°C.

· Temperature Control Method: PID controller with real-time feedback.

· Heating Rate: ≤ 5°C/s (adjustable).

· Temperature Uniformity:

o Across Plate Surface: ±2°C

o Stability: ±0.5°C

Process Control System

· Control Interface:

o 10-inch TFT touch screen display.

o Multi-language support: English, Chinese, etc.

· Programmable Parameters:

o Temperature profiles (up to 5 stages).

o Pressing force/time sequences.

o Cooling cycles.

· Data Logging:

o Internal storage capacity: 2 GB (up to 100,000 cycles).

o Export Format: CSV via USB or Ethernet.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 50 kW

· Control Voltage: 24V DC for safety and signal integrity.

Safety Features

· Emergency Stop: Dual redundant emergency stop buttons.

· Overload Protection:

o Real-time pressure monitoring.

o Automatic shutdown on force deviation >10%.

· Temperature Safety: Independent thermal fuse and overheat alarm at 260°C.

· Operator Safety: Protective safety shields with interlock switches.

Environment & Installation

· Operating Environment:

o Temperature: 10–35°C

o Humidity: ≤70% RH (non-condensing).

· Noise Level: ≤70 dB under standard operation.

· Installation Requirements:

o Level concrete foundation.

o Minimum clearance: 500 mm on all sides.

Optional Configurations

· Mold Customization: Precision molds tailored to customer specifications.

· IoT Connectivity: Real-time monitoring and diagnostics via cloud platform.

· Automatic Loading/Unloading: Robotic module integration for higher throughput.

Maintenance and Warranty

· Scheduled Maintenance:

o Heating elements: Every 12 months.

o Pressing mechanism lubrication: Every 6 months.

· Warranty Period:

o Standard: 12 months.

o Extended options available.