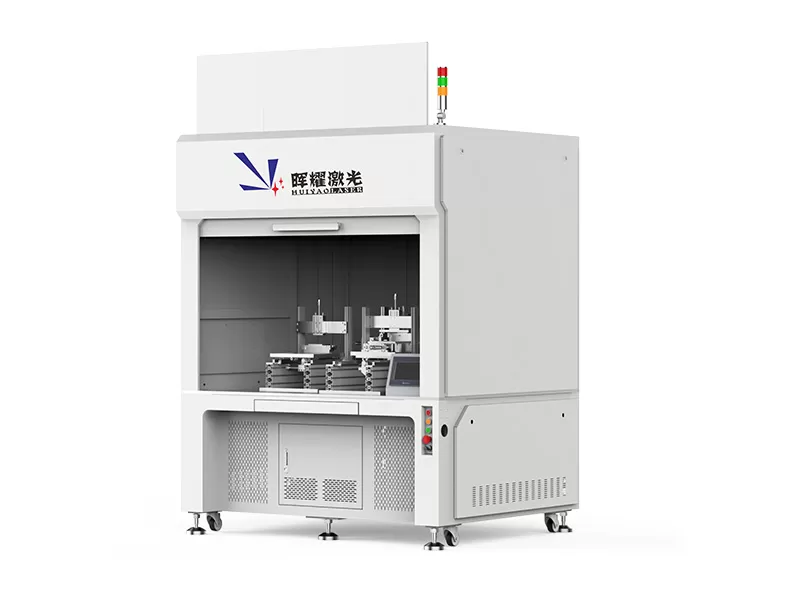

Mechanical Specifications

· Equipment Dimensions:

o Length: 1500 mm

o Width: 1200 mm

o Height: 1800 mm

· Weight: 800 kg

· Frame Material: High-strength steel frame with anti-corrosion coating.

· Worktable Material: Anodized aluminum with anti-static and wear-resistant surface.

· Wrapping Mechanism: Servo-driven rollers with precision tension control.

Wrapping Process Specifications

· Film Material: Mylar, PET, or other insulation films.

· Film Thickness Range: 0.02–0.1 mm.

· Cell Size Compatibility:

o Width: 50–200 mm.

o Height: 50–400 mm.

o Thickness: 20–85 mm.

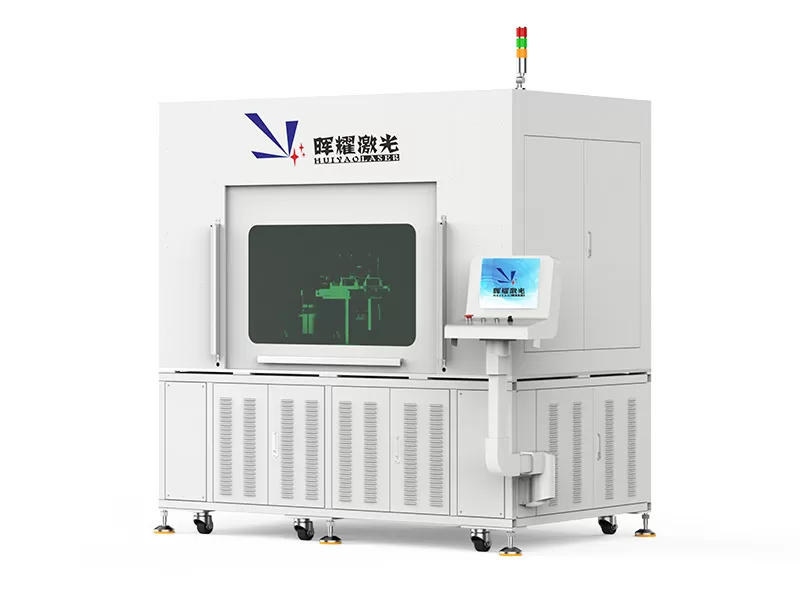

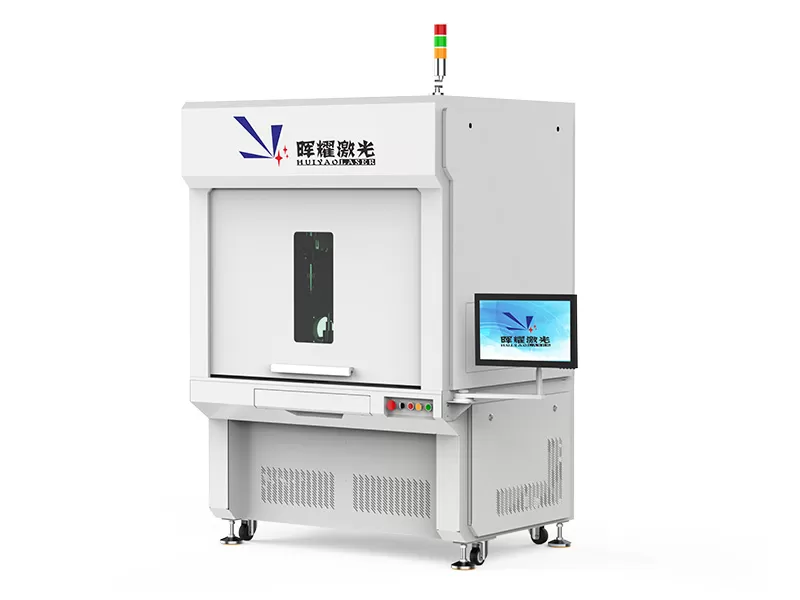

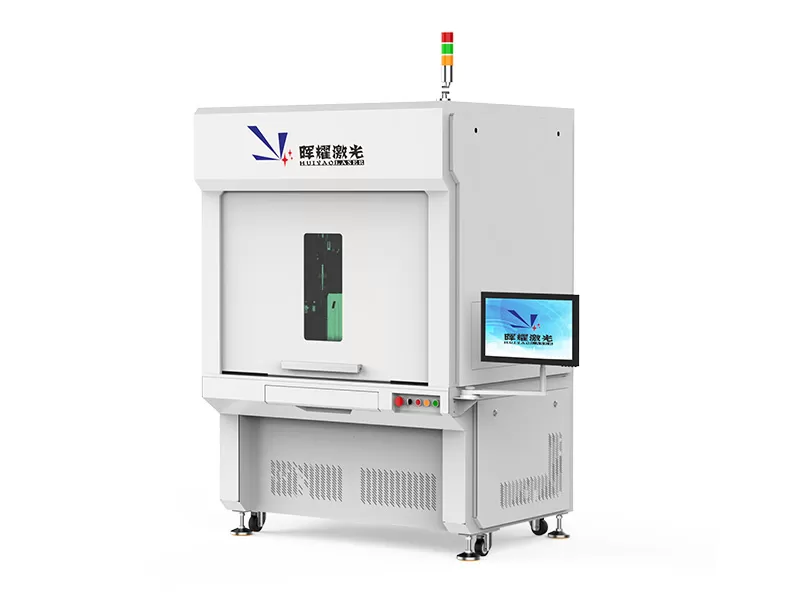

Control and Interface

· Control System: PLC with integrated HMI for real-time operation.

· Interface:

o 10-inch capacitive touchscreen.

o Multi-language support (English, Chinese, others).

· Programmable Parameters:

o Film tension, overlap, and wrapping speed.

o Cutting length and sealing temperature.

o Recipe storage for different battery configurations.

· Data Logging:

o Internal Capacity: 500 GB for process history.

o Export Formats: CSV via USB, Ethernet, or Wi-Fi.

Electrical Specifications

· Power Supply: AC 220V ± 10%, 50/60 Hz, single-phase.

· Maximum Power Consumption: 4 kW.

· Control Voltage: 24V DC for auxiliary systems.

Safety Features

· Emergency Stop: Dual emergency stop buttons on the front and rear panels.

· Film Tension Monitoring: Automatic halt on over-tension or film breakage.

· Protective Enclosure: Transparent cover with interlock mechanism.

· Thermal Safety: Overheat protection for sealing and adhesive systems.

Environment & Installation

· Operating Environment:

o Temperature: 10–30°C

o Humidity: ≤65% RH (non-condensing).

· Noise Level: ≤70 dB during operation.

· Installation Requirements:

o Flat and vibration-free surface.

o Clearance: Minimum 600 mm on all sides.

Optional Configurations

· Customized Wrapping Profiles: For non-standard battery dimensions or shapes.

· IoT Connectivity: Cloud-based monitoring and predictive maintenance.

Maintenance and Warranty

· Maintenance Schedule:

o Monthly: Inspect servo motors and alignment systems.

o Quarterly: Calibrate sensors and lubricate moving parts.

· Warranty Period:

o Standard: 12 months.

o Extended: Up to 36 months available upon request.