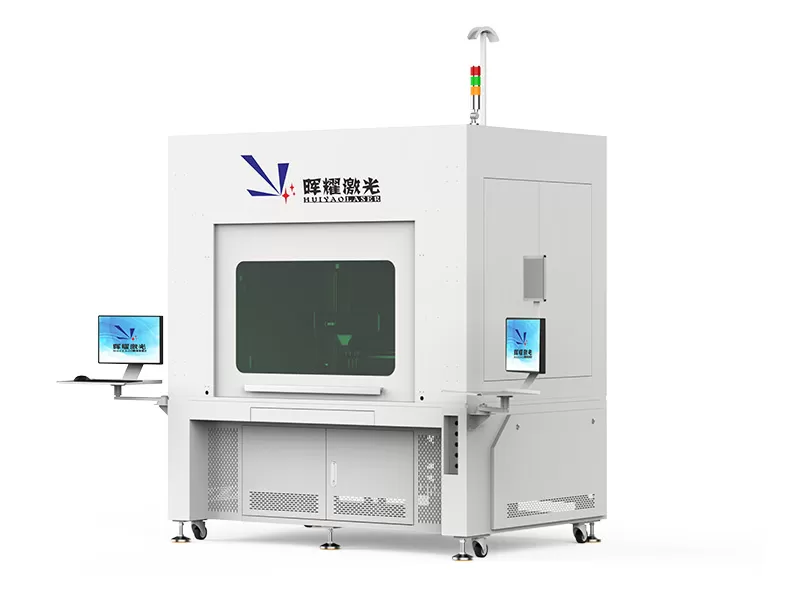

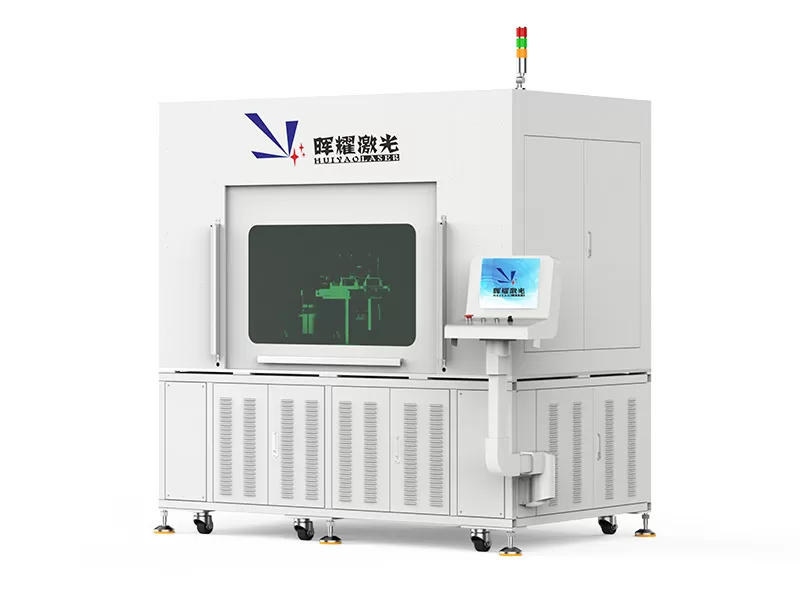

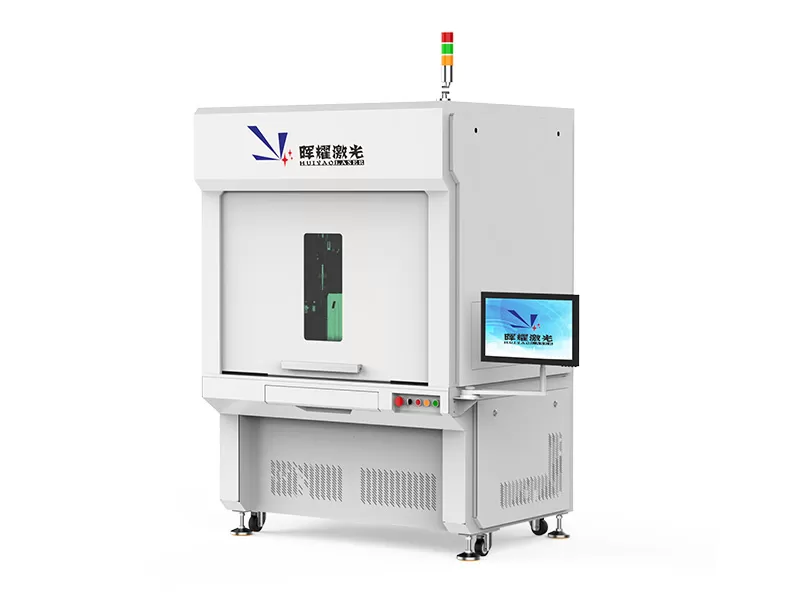

Mechanical Specifications

· Equipment Dimensions:

o Length: 1600 mm

o Width: 1200 mm

o Height: 2100 mm

· Weight: 1500 kg ± 5%

· Frame Material: Industrial-grade steel frame with anti-corrosion treatment.

· Worktable Material: Hardened stainless steel with anti-static and wear-resistant coating.

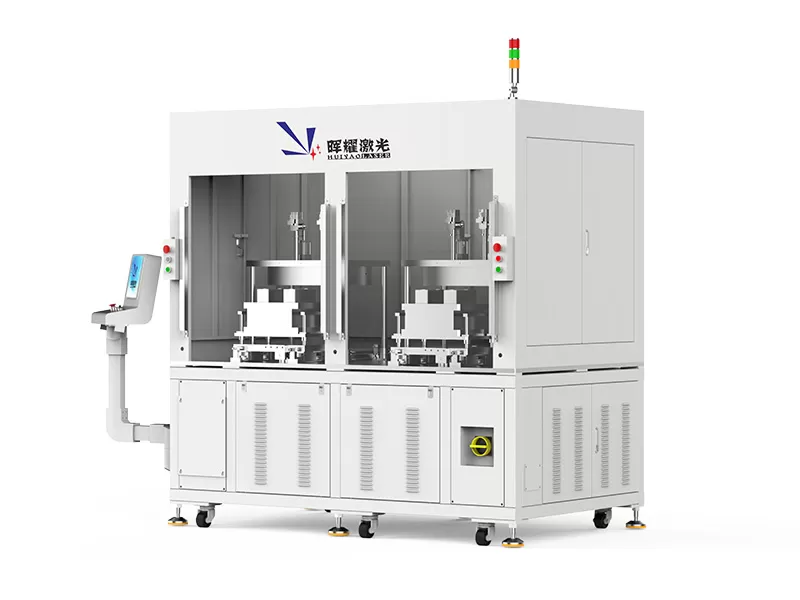

· Motion System: Precision servo-driven X-Y-Z axes with linear guide rails.

Welding Specifications

· Welding Technology:

o Laser Welding (standard).

· Laser Type: Fiber laser, 1064 nm wavelength.

· Laser Power: 3000W–6000 W (adjustable).

· Spot Size: 0.1–0.5 mm (configurable).

· Welding Speed: 5–12 welds per minute, depending on material and thickness.

· Welding Accuracy: ±0.05 mm.

· Transition Sheet Compatibility:

o Thickness: 0.1–1.5 mm.

o Materials: Aluminum, nickel, copper, and laminated sheets.

· Tab Compatibility: Aluminum, nickel, copper, and multi-layer combinations.

Vision and Alignment System

· Alignment Accuracy: ±0.03 mm.

· Camera:

o Type: Industrial-grade high-resolution CCD camera.

o Resolution: 5 MP.

· Lighting System: Adaptive LED illumination for consistent weld seam visibility.

· Error Detection: Automated detection of material misalignment, contamination, and weld defects.

Control and Interface

· Control System: Based on welding control card with integrated HMI (Human Machine Interface)

· Interface:

o 19-inch display with intuitive user interface

o Multi-language support (English, Chinese, others).

· Programmable Parameters:

o Laser power, duration, and spot size.

o Weld patterns and sequences.

o Recipe management for different battery models.

· Data Logging:

o Internal Capacity: 1 TB SSD for weld history storage.

o Export Formats: CSV and PDF via USB, Ethernet, or Wi-Fi.

Electrical Specifications

· Power Supply: AC 380V ± 10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 36 kW.

· Control Voltage: 24V DC for internal systems.

Safety Features

· Emergency Stop: Dual redundant emergency stop buttons.

· Overload Protection: Automatic shutdown upon detecting overcurrent or excessive force.

· Laser Safety: Enclosed laser operation with Class 1 protective casing and interlocks.

· Temperature Monitoring: Real-time monitoring of weld area and cooling system.

Environment & Installation

· Operating Environment:

o Temperature: 10–30°C

o Humidity: ≤65% RH (non-condensing).

· Noise Level: ≤75 dB during operation.

· Installation Requirements:

o Flat, vibration-free surface.

o Minimum clearance: 800 mm on all sides.

Cooling System

· Type: Water-cooled laser module with independent chiller.

· Cooling Capacity: 18KW

· Flow Rate: 65L/min

Optional Configurations

· Dual Welding Heads: For increased productivity and simultaneous processing.

· IoT Connectivity: Remote monitoring and diagnostics via cloud platform.

· Custom Transition Sheet Molds: For non-standard sheet sizes and shapes.

· Integrated Pre-Weld Cleaning: Ultrasonic or laser cleaning module to ensure material surface quality.

Maintenance and Warranty

· Maintenance Schedule:

o Weekly: Clean lens, inspect worktable, and check laser alignment.

o Monthly: Inspect servo motors, cooling system, and electronic connections.

o Quarterly: Full calibration of alignment and welding systems.

· Warranty Period:

o Standard: 12 months.

o Extended: Up to 36 months upon request.