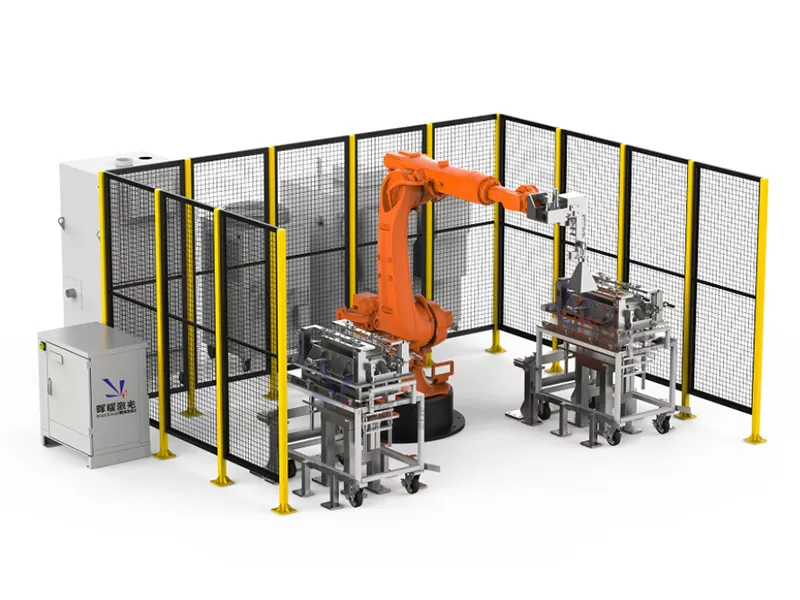

1. Robotic Arm

· Type: 6-axis articulated robotic arm.

· Payload Capacity: 6–20 kg.

· Reach: 1,200–2,000 mm.

· Positioning Accuracy: ±0.05 mm.

· Speed: Up to 1.5 m/s for welding tasks.

· Control System: Integrated motion controller with support for complex path programming.

2. Laser Welding System

· Laser Type: Fiber laser or diode laser (depending on configuration).

· Laser Power: 500 W – 6,000 W.

· Wavelength: 1,070 nm (for fiber lasers).

· Welding Accuracy: ±0.05 mm.

· Welding Modes:

o Spot welding.

o Continuous seam welding.

o Deep penetration welding.

· Weld Speed: Up to 500 mm/s (material dependent).

3. Workstation Design

· Work Area Dimensions:

o Width: 1,500–3,000 mm.

o Depth: 1,000–2,000 mm.

o Height: 1,500–2,000 mm.

· Enclosure:

o Fully enclosed structure with laser safety features.

o Large access doors for loading and unloading.

· Workholding: Adjustable and interchangeable fixtures for diverse components.

4. Vision and Monitoring System

· Camera Type: High-resolution CCD or CMOS cameras.

· Resolution: 8 MP or higher.

· Monitoring: Real-time process monitoring and weld quality assurance.

· Alignment: Automatic part alignment and positioning based on CAD data.

5. Cooling System

· Type: Water-cooled laser and optics.

· Cooling Capacity: 5–10 kW.

· Flow Rate: 20–50 L/min.

· Temperature Control: ±1°C.

6. Control System

· Interface:

o 15-inch touchscreen HMI.

o Multi-language support (English, Chinese, etc.).

· Programming:

o Offline programming for complex welding paths.

o CAD/CAM integration for seamless design-to-weld workflows.

· IoT Connectivity:

o Remote monitoring and data analytics.

o Predictive maintenance capabilities.

7. Electrical Specifications

· Power Supply: AC 380V ±10%, 50/60 Hz, 3-phase.

· Maximum Power Consumption: 20–50 kW.

· Control Voltage: 24V DC for sensors and peripherals.

8. Environmental Requirements

· Operating Conditions:

o Temperature: 10–35°C.

o Humidity: ≤60% RH (non-condensing).

· Noise Level: ≤75 dB.

· Fume Extraction: Integrated system for smoke and particulate removal.